- BY Kevin Barry BSc(Hons) MRICS

- POSTED IN Latest News

- WITH 0 COMMENTS

- PERMALINK

- STANDARD POST TYPE

In UK construction, productivity increases are difficult to implement, especially in the procurement side of the equation. COVID-19 has forced a reassessment of supply and demand and the construction industry has to respond to survive !

In tendering and estimating, the advent of computers, spreadsheets and more specific software has assisted in the use of technology.

In general estimating, the slowest area is the generation of quantities beyond digitizing areas from drawings, and subsequent changes in the specification of the same quantities throughout the various elements of a building.

Over the past six years, QUINTIN QS has tried to improve on this problem. When measurements are captured, those same measurements can be used repeatedly in conjunction with other differing measurements to generate quantities for various elements of work.

We have developed an Excel based system to allow entry of key measurements once, thus facilitating the automatic generation of the other quantities required, and cross checked to ensure accuracy.

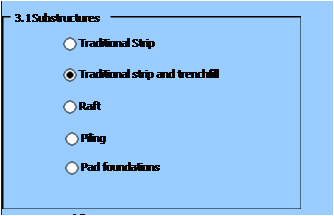

Coupled with this, we have established an elemental toggle click, as shown below for 3.1 Substructures. All typical BCIS elements have a similar approach to the selection of various materials.

Once the basic costing generated, we can toggle between the 5 different scenarios to ascertain the change in cost instantly. Also, key dimensions can be changed in order to assess the cost effect of various designs.

This process is repeated for all elements of a typical building incorporating innovation and automation combined with professional awareness and more accurate assessment of cost variances. A matrix may be provided, showing the out-turn cost for various changes in the specification of each element, all within a very short time period, measured in minutes, not days.

System is currently used in appraisal of schemes on the client side and being introduced for builders/sub-contractors pricing.